Our company “SAHANA ENGINEERING” is the leading and developing manufacturer, supplier and trader of Ultrasonic Level Transmitter in Coimbatore.

Our Ultrasonic Level Transmitter manufacturer in Pune creates these transmitters that work by using the speed of sound as given in ‘Time of Flight’ as their working principle for adequate result for our valuable clients. We suppliers in Pune provide a huge variety of these level transmitters that are able to emit pulses of higher frequency range for easy measurement of liquids.

ULTRASONIC LEVEL TRANSMITTERS are the devices consisting of ultrasonic level sensors for measuring the desired distance by using the ultrasonic waves. These are the level sensing technology of non contacting nature

working in the same manner as compared to the sonar or radar.

The ultrasonic sensors have two basic components that are the transmitter and receiver. These transmitters consist of piezoelectric transducers

which produce sound waves of greater frequency within the ultrasonic range.

| Electronics Housing | Stainless Steel or die cast aluminium, flame proof |

| Temperature | 0 to 65 deg C |

| Applications | Liquids including hazardous but non-corrosive medium |

| Input Supply | 24V DC |

| Analog output (Programmable) | 4 – 20mA, 20 – 4 mA, 0 – 10 V DC, 10 – 0 V DC |

| Mode | Distance OR height measurement |

| Display | 8 x 2 alphanumeric displya, “ 7 segment LED ” |

| Communcation | RS 485 – Modbus |

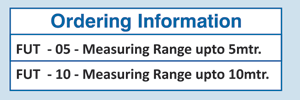

| Measuring range | 5mtr, 10mtr ,0.5mtr, 1 mtr, 3.5 mtr |

| Resolution | 1mm, 5mm or 10mm depending on models |

| Accuracy | 0.5% of FSD |

| Updation time | 150 mS max |

| Minimum distance | 40mm to 300mm depending on range |

| Display Filter | None / Low / Medium / High |

| Temperature compensation | Inbuilt |

| Voltage Variations | Internal calibration and automatic compensation |

| Process connections | ½” BSP, 1 ½” BSP |

| Electrical connections | PG 9 one gland, 2 numbers |

| Sensor face | Anodised aluminium |

| Sensor body | PVC |